| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : hsd

Certification : CE, ISO, RoHS

Place of Origin : China

MOQ : 1

Price : US$100,000.00 - 3,000,000.00

Payment Terms : T/T,L/C,D/A

Supply Ability : 30 sets/year

Delivery Time : 60 days

Packaging Details : Standard Package for Export

Coating : Powder Coating

Coating Material : Epoxy Powder, Adhesive, Polyethylene

Surface Treatment : Grade≥SA2.5

Specification : Φ 48mm– Φ 2400mm

Substrate : Steel

Coating Type : Internal, External

Heating Method : Induction Heating

The three-layer polyethylene (3LPE) process uses fusion-bonded epoxy (FBE) as the bottom layer, adhesive (AD) as the middle layer, and polyethylene (PE) as the outer layer. This structure provides superior corrosion protection for steel pipes, extending service life from 5-10 years to 50-100 years.

It is widely applied in oil and gas pipelines, as well as urban gas and water supply pipelines. The 3LPE coating offers high mechanical strength, excellent electrical insulation, and strong resistance to environmental degradation.

Technological Process

Pipe loading

Screw conveyor transportation

Rust removal & intermediate frequency heating

Epoxy powder coating (FBE)

Outer adhesive & PE coating (solid/liquid)

Cooling spray

Screw conveyor transportation

Grinding

Pipe unloading

Coating Structure & Thickness

First layer: Fusion bonded epoxy (FBE) > 100 μm

Second layer: Adhesive (AD) 170-250 μm

Third layer: Polyethylene (PE) 2.5-3.7 mm

Available Pipe Diameter Ranges (Four main models):

Φ48-219 mm

Φ219-1220 mm

Φ800-1600 mm

Φ1000-2400 mm

Descaling Grade: SA 2.5

Coating Thickness: 80-800 μm

Standards Compliance: SY/T0413-2002, GB/T23257-2009, DIN 30670, DIN 30678, American Corrosion Association, DNV, SY/T0315-2005, CNPC38-2002, and related international standards.

Production Capacity

Max. output: 3-8 km/day (depending on pipe diameter)

Annual capacity: 2 million m² (for Φ508 mm pipes)

| Steel pipe outside shot blasting derusting operation line | |||

| No. | Description | Qty. | Remarks |

| 1 | Transmission line | 1set | |

| 2 | Shot blasting derusting line | 1set | |

| 3 | Cyclone dust collector | 1set | |

| 4 | Pulse filter cartridge dust collector | 1set | |

| 5 | Centrifugal wind blower | 1set | |

| 6 | Derusting equipment electrical control system | 1set | |

| Steel pipe outside spiral 3PE production line | |||

| No. | Description | Qty. | |

| 1 | Coating transmit system | 1set | |

| 2 | Intermediate frequency heating system | 1set | |

| 3 | Epoxy spraying system | 1set | |

| 4 | Automatic feeding dryer | 2sets | |

| 5 | SJ-65/30 single screw high efficiency extruder | 1set | |

| 6 | SJ-120/30 extruder | 1set | |

| 7 | Hot melt adhesive extrusion die head | 1set | |

| 8 | PE sheet extrusion die head | 1set | |

| 9 | Hot melt adhesive/PE sheet press device | 1set | |

| 10 | Stainless steel spray powder chamber | 1set | |

| 11 | Cooling water spray system | 1set | |

Platform system | |||

| No. | Description | Qty. | |

| 1 | Steel pipe up load platform | 1set | |

| 2 | Derusting transition platform | 1set | |

| 3 | Finished pipe storage system | 1set | |

| 4 | Hydraulic system | 3sets | |

| Grooving system | |||

| No. | Description | Qty. | |

| 1 | PE grooving device | 2sets | |

| 2 | Hydraulic elevating pipe turner | 2sets | |

| 3 | Operating cabinet | 1set | |

Qingdao Huashida is one of the largest professional manufacturers and exporters of anti-corrosion and insulation equipment in China. With over 20 years of experience and strong R&D capabilities, we offer both standardized and customized solutions for global clients.

Our main products are:

Our team

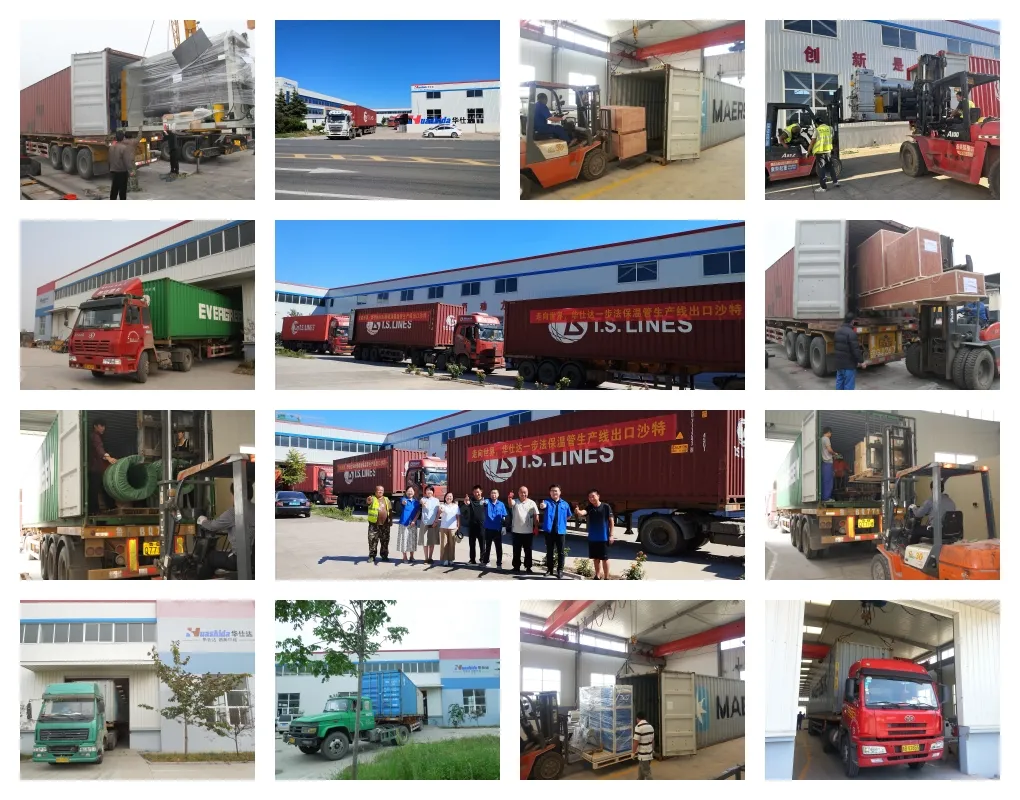

Delivery

Exhibition

Certifications

|

|

3LPE Coating Line for Steel Pipes with FBE and Polyethylene Images |