| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HUASHIDA

Model Number : 50-4200MM

Certification : CE, ISO

Place of Origin : qingdao,china

MOQ : 1

Price : US$100,000.00 - 3,000,000.00

Payment Terms : L/C,T/T,Western Union,MoneyGram

Supply Ability : 30 Sets/Year

Delivery Time : 60days

Packaging Details : Standard packaging

Coating : Powder Coating

Surface Treatment Grade : ≥SA2.5

Type : Coating Production Line

Coating Material : Epoxy Powder, Adhesive, Polyethylene

Highlights : PLC automatic control system

| Attribute | Value |

|---|---|

| Coating | Powder Coating |

| Surface Treatment Grade | ≥SA2.5 |

| Type | Coating Production Line |

| Coating Material | Epoxy Powder, Adhesive, Polyethylene |

| Highlights | PLC automatic control system |

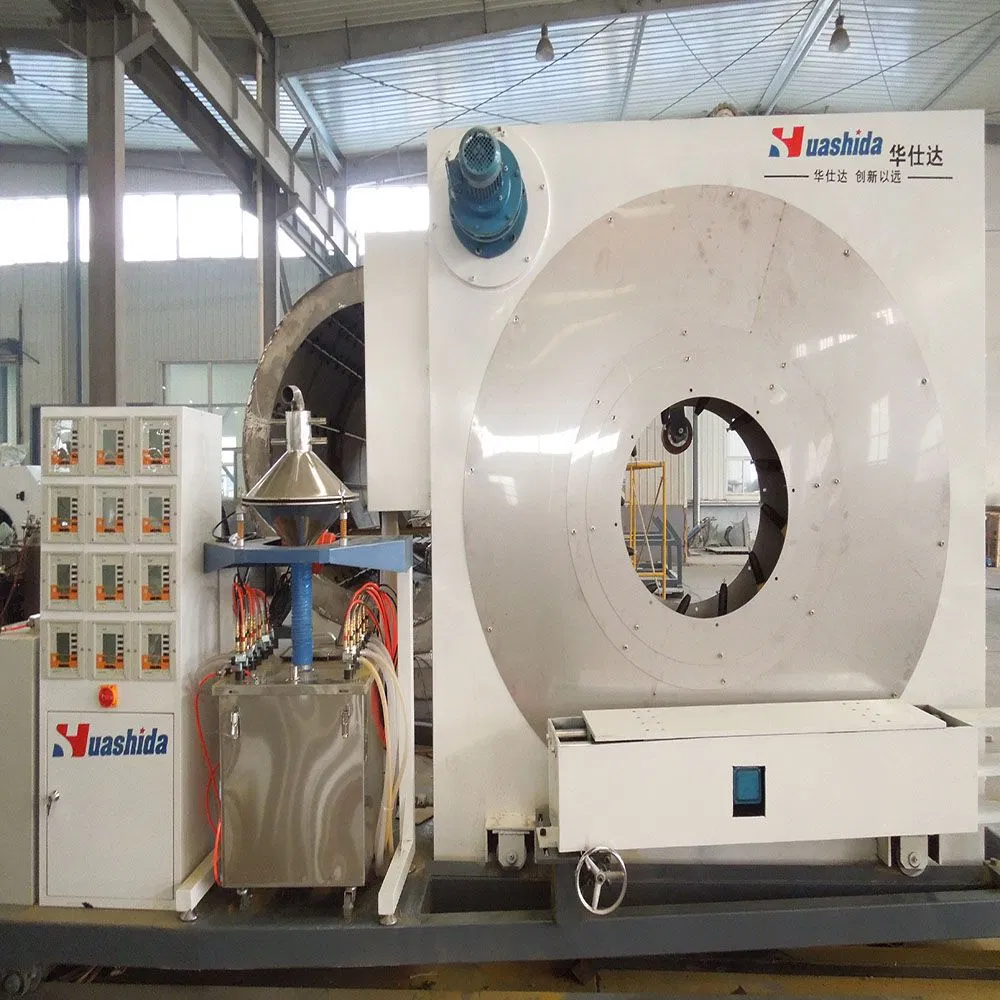

The 3LPE/FBE anticorrosion insulation pipeline coating system is specifically engineered for oil and gas pipelines, offering superior protection against corrosion and environmental damage.

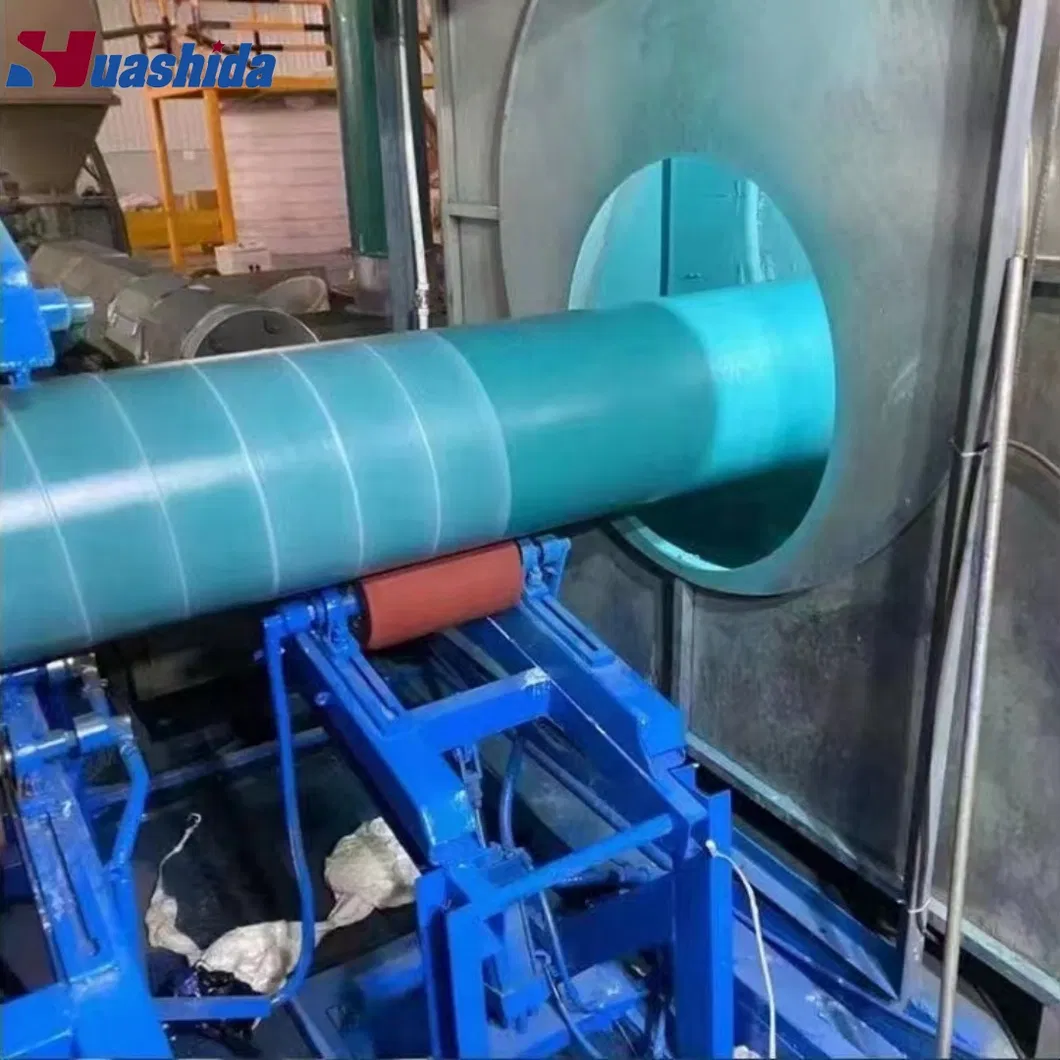

Our 3PE anti-corrosion coating production line features a three-layer PE anti-corrosion structure, with a diameter range of φ50 ~ φ4200, designed for comprehensive pipeline protection.

Qingdao Huashida Machinery Co., Ltd. offers customized production capabilities to meet diverse customer requirements for high-performance 3PE coating solutions.

This system is widely used in gas and oil transmission lines, municipal gas supply systems, water pipes, and other fluid transport conduits, enhancing mechanical capabilities while providing superior protection.

Upload pipes → Pipes screw conveyor → Rust removal with intermediate frequency heating → Epoxy powder coating → Outer layer solid & polyethylene coating → Cooling spray → Pipes screw conveyor → Grinding pipes → Unload pipes

| A. Derusting Equipment | ||

|---|---|---|

| 1 | Pipe wheel conveyor | 1 |

| 2 | Shot Blasting Machine | 1 |

| 3 | Cyclone Dust Collector | 1 |

| 4 | Pulse dust collector | 1 |

| 5 | Centrifugal exhaust fan | 1 |

| 6 | Rust removal equipment PLC | 1 |

| B. Coating Equipment | ||

| 1 | Pipe wheel conveyor | 1 |

| 2 | Induction heating device | 1 |

| 3 | Powder spraying device | 1 |

| 4 | Automatic loading dryer | 2 |

| 5 | SJ-65/30 Extruder | 1 |

| 6 | SJ-120/30 Extruder | 1 |

| 7 | Hot melt adhesive extruder die | 1 |

| 8 | PE sheet extruder head mold | 1 |

| 9 | Hot melt adhesive/PE sheet coating device | 1 |

| 10 | Environmental Protection Ventilation equipment | 1 |

| 11 | Cooling Spray equipment | 1 |

| C. Platform Equipment | ||

| 1 | Steel pipe uploading platform | 1 |

| 2 | Downloading platform | 1 |

| 3 | Pipe storage platform | 1 |

| 4 | Turnover mechanism | 3 |

| D. Groove Equipment | ||

| 1 | PE Beveling Machine | 2 |

| 2 | Hydraulic Lifting and Turning Machinery | 1 |

| 3 | Hydraulic Equipment | 1 |

| 4 | PLC automatic control system | 1 |

Corrosion-resistant steel pipes are categorized into internally treated and externally treated types. Internally treated pipes use protective coatings, while externally treated pipes primarily feature 3PE coating technology.

Qingdao Huashida's 3PE anti-corrosion production line utilizes mature technology to provide effective protection for both pipe interiors and exteriors. Suitable for various pipe types including straight-seam and spiral pipes, our production line features a comprehensive ISO9001-certified quality assurance system.

Qingdao Huashida Machinery Co., LTD., founded in 2003, is a global developer, manufacturer and solution provider of plastic extrusion equipment. 70% of our customers come from overseas markets including Europe, America, the Middle East and Southeast Asia.

We welcome you to visit our factory to discuss potential cooperation opportunities!

|

|

20 Year Professional 3PE 3lpe Fbe Anti-Corrosion Coated Steel Pipe Production Line Images |