| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : Huashida

Model Number : 50-4200mm

Certification : CE, ISO, RoHS

Place Of Origin : Qingdao,China

MOQ : 1 Set

Price : $US100000-3000000

Payment Terms : TT/LC/DP

Supply Ability : 30 Set/year

Delivery Time : 60 Days

Packaging Details : Standard Package For Export

Place : Indoor

Cleaning Level : SA2.5

Extruder : Single Screw Extruder

Method Type : Automatic

Coating Materials : Polyethylene, Adhesive, Epoxy

Model No : Pipe Dia. 50-4200mm

Coating Material : Epoxy Powder, Adhesive, Polyethylene

Substrate : Steel

Coating : Powder Coating

Huashida 3LPE steel pipe blasting & coating equipment is designed for water, gas, and oil pipeline anti-corrosion processing according to customers' specific requirements. The production line includes internal and external shot blasting for derusting, dual Fusion Bonded Epoxy (FBE) powder or liquid coating, PE/PP film wrapping, PE end grooving system, and more.

1.High Quality, Competitive Price, and Excellent Service: Huashida's 3PE anti-corrosion coating production line features superior equipment quality, an affordable price, and outstanding service. The three-layer PE pipelines produced using this production line rank at the forefront of the oil and gas transportation industry. For instance, the nearly 4,000 km pipeline of the national key project - the West-East Gas Transmission Project, utilizes pipelines with three-layer PE anti-corrosion coatings. These pipelines are also widely used in natural gas production projects.

2.Comprehensive Production Process:

Pipe loading → External derusting → Inner blowing cleaning → Epoxy coating application → Adhesive application on the epoxy layer → PE jacket coating → Water cooling → Coating layer inspection → Pipe edge treatment → Finished pipe conveyance → Pipe unloading

Wide Diameter Range: The 3PE anti-corrosion coating production line can handle pipes with diameters ranging from Φ57mm to Φ1620mm, enabling one-stop pipeline operations.

Three-Layer PE Anti-Corrosion Structure with Complementary Advantages: The three-layer PE anti-corrosion structure combines the excellent anti-corrosion properties of epoxy coatings and extruded polyethylene. The epoxy coating offers superior interface characteristics and chemical resistance, while the extruded polyethylene coating provides excellent mechanical protection. The combination of these two properties significantly enhances the overall anti-corrosion performance.

First Layer: Epoxy powder (FBE > 100µm), which provides basic anti-corrosion protection for the pipeline.

Second Layer: Adhesive (AD) with a thickness of 170 - 250µm, which acts as a bonding agent to ensure tight adhesion between the layers.

Third Layer: Polyethylene (PE) with a thickness of 2.5 - 3.7mm, which offers robust mechanical protection for the pipeline.

This anti-corrosion structure, composed of an underlying epoxy powder layer, an intermediate adhesive layer, and an outer polyethylene layer, integrates the three materials into one and forms an excellent anti-corrosion layer firmly bonded to the steel pipe. After years of practical application, the buried three-layer outer protective layer of the pipeline has proven to be highly superior. It has gained full international recognition and widespread promotion, with a service life of over 50 years.

| Steel pipe outside shot blasting derusting operation line | |||

| No. | Description | Qty. | Remarks |

| 1 | Transmission line | 1set | |

| 2 | Shot blasting derusting line | 1set | |

| 3 | Cyclone dust collector | 1set | |

| 4 | Pulse filter cartridge dust collector | 1set | |

| 5 | Centrifugal wind blower | 1set | |

| 6 | Derusting equipment electrical control system | 1set | |

| Steel pipe outside spiral 3PE production line | |||

| No. | Description | Qty. | |

| 1 | Coating transmit system | 1set | |

| 2 | Intermediate frequency heating system | 1set | |

| 3 | Epoxy spraying system | 1set | |

| 4 | Automatic feeding dryer | 2sets | |

| 5 | SJ-65/30 single screw high efficiency extruder | 1set | |

| 6 | SJ-120/30 extruder | 1set | |

| 7 | Hot melt adhesive extrusion die head | 1set | |

| 8 | PE sheet extrusion die head | 1set | |

| 9 | Hot melt adhesive/PE sheet press device | 1set | |

| 10 | Stainless steel spray powder chamber | 1set | |

| 11 | Cooling water spray system | 1set | |

Platform system | |||

| No. | Description | Qty. | |

| 1 | Steel pipe up load platform | 1set | |

| 2 | Derusting transition platform | 1set | |

| 3 | Finished pipe storage system | 1set | |

| 4 | Hydraulic system | 3sets | |

| Grooving system | |||

| No. | Description | Qty. | |

| 1 | PE grooving device | 2sets | |

| 2 | Hydraulic elevating pipe turner | 2sets | |

| 3 | Operating cabinet | 1set | |

Q: What is the brand name of this 3LPE Coating Pipe Production Line?

A: The brand name of this product is Huashida.

Q: What is the model number of this 3LPE Coating Pipe Production Line?

A: The model number of this product is 50-4200mm.

Q: Where is this 3LPE Coating Pipe Production Line manufactured?

A: This product is manufactured in Qingdao, China.

Q: What certifications does this 3LPE Coating Pipe Production Line have?

A: This product is certified with ISO, CE, and RoHS certifications.

Q: What is the minimum order quantity for this 3LPE Coating Pipe Production Line?

A: The minimum order quantity for this product is 1 set.

Qingdao Huashida is one of the largest professional manufacturers and exporters of anti-corrosion and insulation equipment in China. With over 20 years of experience and strong R&D capabilities, we offer both standardized and customized solutions for global clients.

Our main products are:

Our team

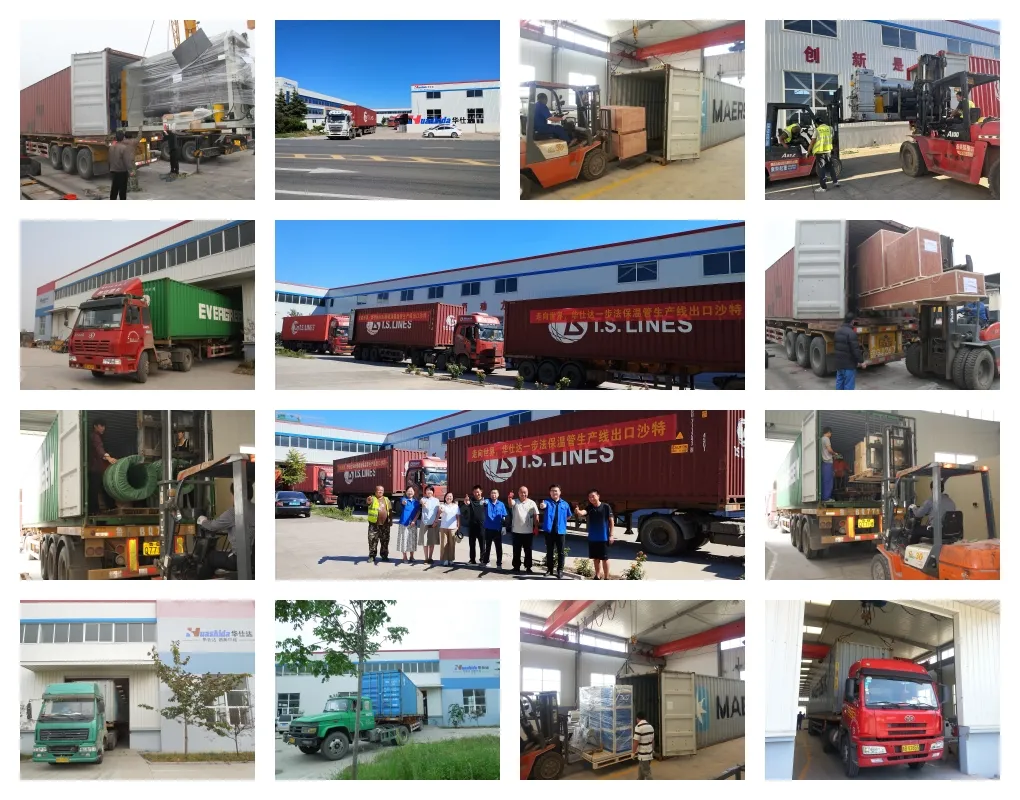

Delivery

Exhibition

Certifications

|

|

Automatic 3LPE Coating Machine for Steel Pipes 50-4200mm Diameter Images |