| Sign In | Join Free | My carsrow.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My carsrow.com |

|

Brand Name : HUASHIDA

Certification : ISO9001

Place of Origin : Qingdao,Shandong,China

MOQ : 1

Payment Terms : D/P, L/C, D/A, , T/T, Western Union, MoneyGram

Delivery Time : come to an agreement in respect of the delivery time

Packaging Details : Packing according to Machine

Shot/Grit separator : 100T

Steel shot/grit elevator : 100T

Pulse filter cartridge dust collector : 32 Filter cartridge

Centrifugal induced draft fan : 22KW

Intermediate frequency heater : 300KW

Intermediate frequency lifting frame : Electric lifting

Polyurethane Spraying Prefabricated Insulated Steel Pipe Automatic Production Line

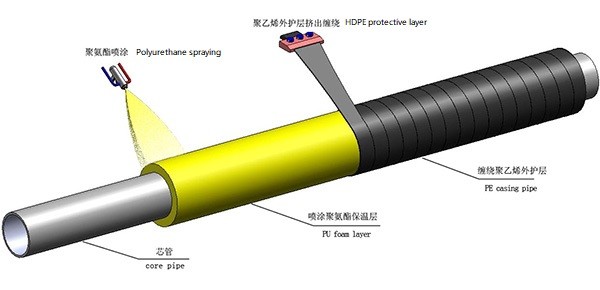

Rigid polyurethane spraying polyethylene winding prefabricated directly buried insulation pipe consists of steel working pipe, spraying polyurethane rigid foam insulation layer and winding polyethylene outer protective pipe. See the following figure for

2. Technological flow:

(1). Steel pipe rust removal: use a hydraulic lifter to transport the steel pipe to conveying line. The steel pipe rotates and enters the shot blasting chamber. When the internal sensor collects the signal of incoming steel pipe, the shot blasting machine starts to work. The shooting projectiles hits the outer surface of the steel pipe, removing rust and impurities attached to pipe surface, and the steel pipe moves onto the conveying line. After shot blasting treatment, the outer surface of the steel pipe meets the requirements of SA2.5.

(2). Polyurethane spraying: The steel pipe moves forward at a constant speed on rotating wheels. The spraying robot blow foaming materials to form umbrella shaped fog to evenly spray it onto surface of the rotating steel pipe. The polyurethane raw materials foam within a short period of time to achieve the required compressive strength and design thickness. When the insulation layer is very thick, multiple times of spraying can be required.

(3). Polyethylene pipe winding: The steel pipe that has been coated with polyurethane insulation layer rotates and moves along the conveying line. The extruder extrudes a certain thickness of molten polyethylene sheet and winds it on outer surface of the insulation layer. As the insulated steel pipe continues to move forward, the extruder continuously extrudes the molten polyethylene sheet material and wraps it on the surface of the polyurethane layer to form protective layer.

(4). Spray cooling: The semi-finished pipe wrapped with a polyethylene outer protective layer is cooled by an online spraying device. The polyethylene outer protective layer tightly wraps the polyurethane insulation layer on the steel pipe, completing the production of insulated steel pipe.

(5). Tracking and cutting: online track the pipe and cut automatically. When the sensor detects incoming pipe, the control system automatically starts the cutting saw. While the saw blade rotates at high speed, the cutting mechanism performs circumferential cutting around the pipe. Online cutting not only ensures high quality cutting ends, but also ensures the continuity of production and improves production efficiency.

(6). Number the finished pipe and put pipes into warehouse

3.Technical parameter

|

No. | Steel pipe dia. (DN)

| Foaming thickness(mm) | PE casing dia. | Min. PE thickness |

| 1

| 500

| 30-60

| 598-658

| 4.5

|

| 2

| 600

| 30-60

| 700-760

| 5.0

|

| 3

| 700

| 30-60

| 790-850

| 5.0

|

| 4

| 800

| 30-60

| 891-951

| 5.5

|

| 5

| 900

| 30-60

| 992-1052

| 6.0

|

| 6

| 1000

| 30-60

| 1093-1153

| 6.5

|

| 7

| 1100

| 30-60

| 1194-1254

| 7.0

|

| 8

| 1200

| 40-100

| 1316-1436

| 8.0

|

| 9

| 1400

| 50-100

| 1538-1678

| 9.0

|

| 10

| 1620

| 50-100

| 1738-1840

| 10.0

|

4.Work environment

location : indoor

Power : non hazardous area

Humidity: 85% non condensing

Temperature: 0-35℃

|

|

Polyurethane Spraying Prefabricated Insulated Steel Pipe Automatic Production Line Images |